Gabion

What Is Gabion ?

Basically it is cage made by hexagonal woven wire mesh that can be filled with rocks or other inert material which builds a solid gabion structure used for various eco friendly

construction purpose.

Satyam Buildtech gabion products and application

-

Gabion Box

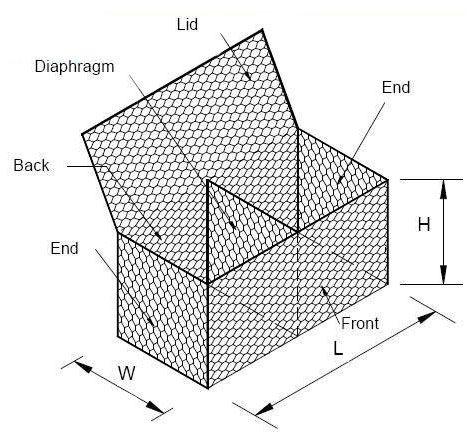

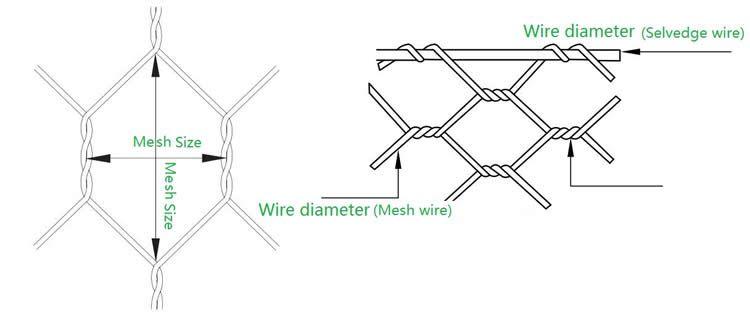

Gabion box is made by double twisted wire mesh container which can be filled with rocks or other inert material. They are widely use for canal, river & coastal protection to avoid soil / sand erosion. Gabion boxes are flexible as well as durable with high strength factor in it. They are available in G.I. coating & PVC coating. There are numerous uses for these modular units and are typically used to form flexible, permeable and monolithic structures such as retaining walls, channel linings, hydraulic control structures and erosion protection. They are increasingly being used in architectural applications as well. Gabion box are made from high-quality wire, which is galvanised. An additional protective polymeric coating is also applied for gabions that are to be used in more aggressive environments, or where a longer design life is required. In order to reinforce the structure, all mesh panel edges are selvedged with a wire having a greater diameter.

-

Gabion Wall

Gabion wall are gravity structure that are considerably strong, flexible, environmentally friendly & cost effective. The gabion wall helps to retain structure & avoid landslides in mountain region & flood prone area. They are available in G.I. coating & PVC coating.

Gabion walls are executed mainly in the purpose of soil stabilization behind the wall, but it can also be executed as a cover wall. The wall is made from gabion baskets that are stacked in one or more rows, depending on the height of the wall. Baskets have a cage shape and are closed on all sides. They are made from a galvanized hexagonal meshes and filled with rocks that are placed in the baskets. Retaining structures are formed by stacking gabion baskets in a proper schedule and present an alternative solution for concrete structures in the area of soil stabilization.

Gabion wall are strong and flexible, which can be backfilled with native rock to ‘blend’ into their background, and thereby, become more aesthetically pleasing. -

Gabion Mattresses

Gabion baskets mattress can be made of hexagonal double- twisted mild steel wire mesh. Mattresses can be supplied in various length, widths and height.

Gabion mattress is made of different materials including galvanized steel wire & PVC coated steel wire. Gabion mattresses are used to slow down river flow to avoid soil erosion of fertile landscape near river bank. These structure are rigid solid & has decent flexibility which ensures long life of the gabion mattresses in harshest environment.

Mattresses and gabion baskets are also available with a 0.5mm thickness P.V.C. coating to enhance the resistance of the baskets to corrosion. This provides an overall increase in diameter of 1mm to all wires used in the manufacturing process.

The river mattress is a structure made of hexagonal double twisted wire mesh. River mattresses are filled with stones at the project site to form flexible and permeable, monolithic structures for river bank protection and channel linings for erosion control.

-

Rockfall Netting

The rockfall netting is commonly used for rock retention over the mountain areas to prevent rock fall, thus minimizing loss of property or life in worst environmental conditions like landslides, earth quake, heavy rainfall etc..

Rockfall net is a steel woven hexagonal wire netting which is used to prevent rocks and debris from falling onto roads, railways and other structures.

The mesh is made of heavily zinc coated or PVC + Heavily Zinc coated double twisted steel woven wire. Due to the characteristics of double twist, the steel wire netting can withstand the force of falling rocks without unraveling in the event of wire breakage.

Steel wire used in the manufacture of the rock fall protection netting is heavily galvanized (zinc coated) mild steel wire. Rockfall protection netting with PVC coating can be used in aggressive environments. In addition to galvanization, the steel wire is coated with a PVC layer of suitable thickness. The technical characteristics and the resistance of the PVC to aging meet the relevant standards.

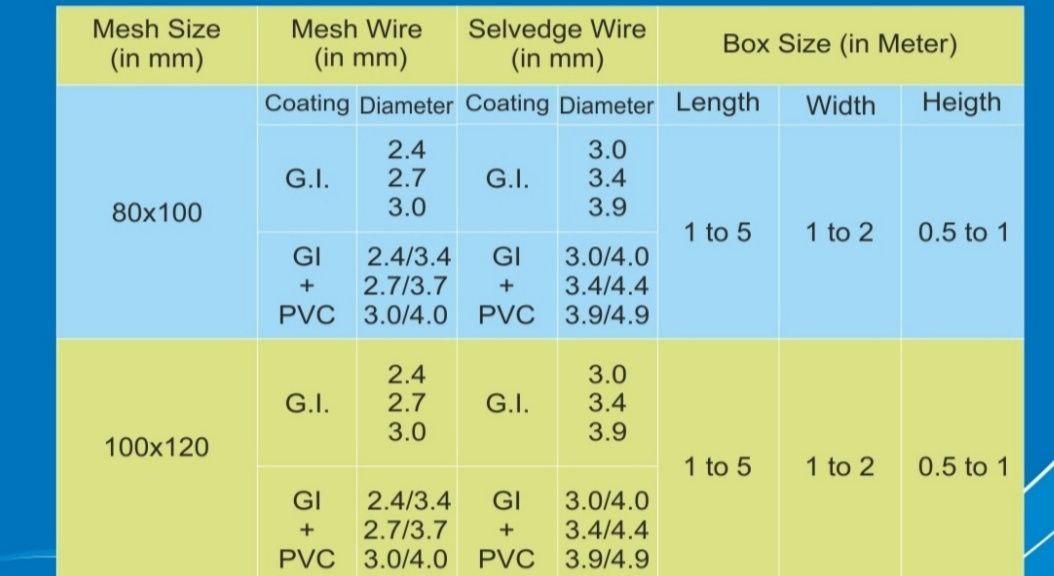

Specifications

- G.I. (Galvanised Iron) Coating upto 275 GSM & available in Galfan wire is covered with Zn-Al (Al 5%, Zn 95% or Al 10%, Zn 90%) alloy.

- Partitions are at every meter in the box

- Example : GI + PVC=3.0/4.0 (internal diameter of GI Wire / external Diameter of GI + PVC coated wire)

- Box dimension can be modified as per your choice

How to use Gabion Box

Assembly

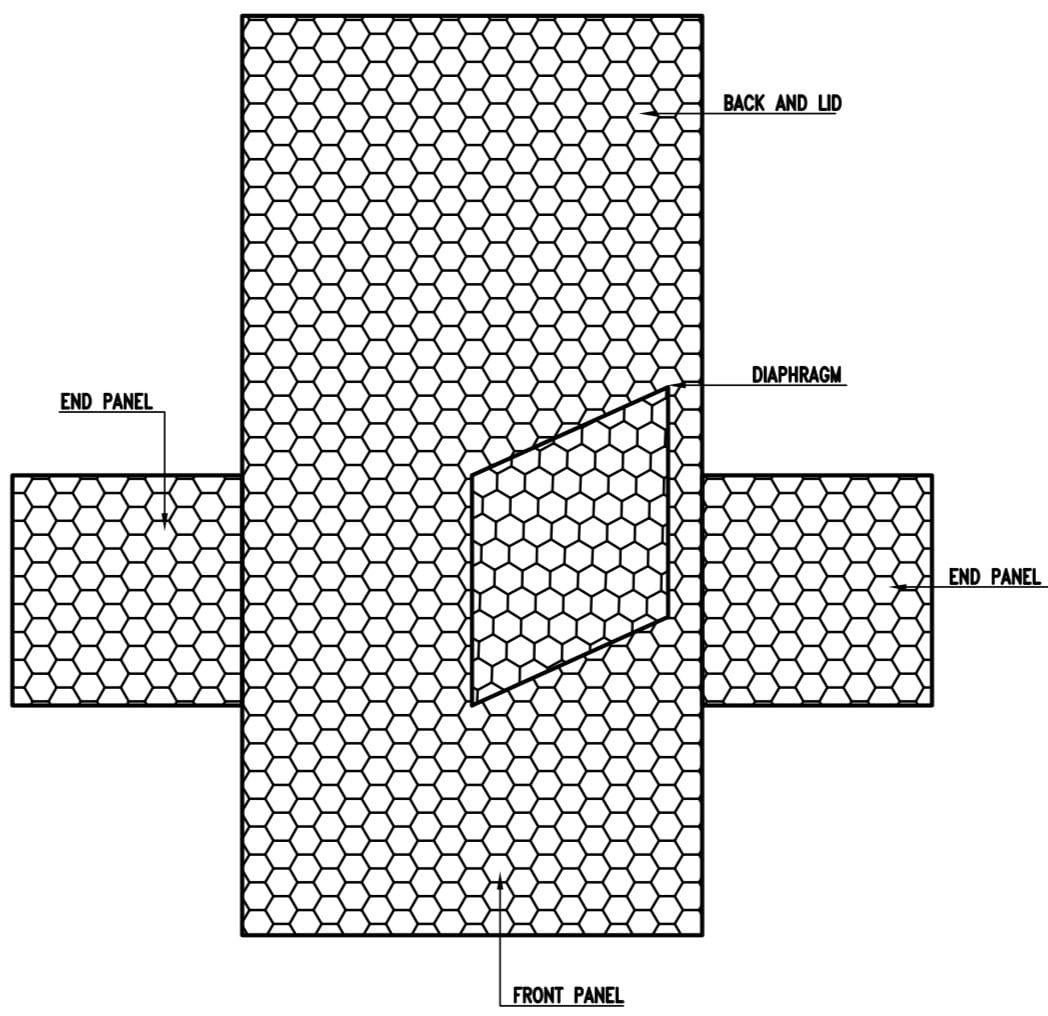

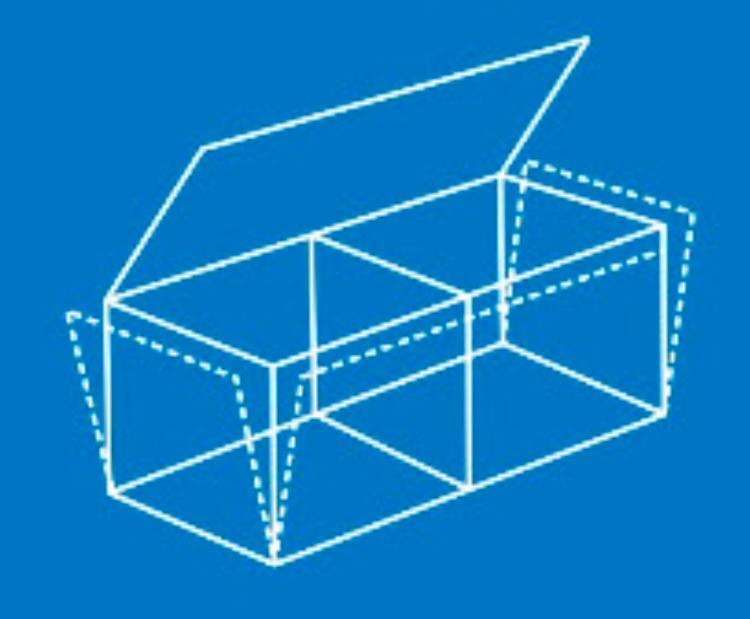

Unfold each gabion on a hard, flat surface. Stretch it out and stamp out any kinks. Make sure that all creases are in the correct positions for Forming the box one at the edge of each end panel and each diaphragm.

Unfold each gabion on a hard, flat surface. Stretch it out and stamp out any kinks. Make sure that all creases are in the correct positions for Forming the box one at the edge of each end panel and each diaphragm.

Fold the side and end panels into the upright position to from a rectangular box. Join the top corners of the box together with the thick selvedge wire sticking out from the corners of each panel. This makes sure that the tops of all four sides of the

box are level.

Begin wiring up by securing the binding wire at the top corners of the panels to be joined by looping it through and twisting it together.

Then lace the wire around the selvedges with single loops and double loops in turn at 100 mm (4 in) interfals.

Finally, fasten the wire securely at the bottom corner, and poke the loose end inside the gabion. Next, lift the diaphragms in to the vertical position,and wire them up to the side panels in exactly the same way.